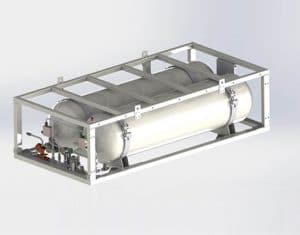

For the skid-mounted hydrogen fueling station, it is to integrate some equipment control components on the container base to form a mobile hydrogen fueling station with a specific function based on the process flow and control requirements of the hydrogen fueling station. The advantage is compact structure, factory manufacturing and installation guaranteeing quality, saving a lot of land, reducing investment costs, and is safe and reliable, which is conducive to operation and maintenance.

The main equipment of containerized hydrogen fueling unit is composed of unloading module (unloading hydrogen from long pipe trailer), compressor module, hydrogen fueling machine module, sequence control module, safety control module, container body module, etc. The containerized hydrogen fueling unit adopts the external hydrogen supply as the hydrogen source. The hydrogen in the long pipe trailer is compressed to 45MPa by a high pressure compressor through the unloading module. The compressed high pressure hydrogen is then stored in the external hydrogen storage cylinder group through the sequence control module or directly supplied to the hydrogen fueling unit module. The sequence control module is used to realize the hierarchical hydrogenation mode control function. By monitoring the hydrogen pressure of each channel entering the sequence control module, the hydrogen pressure of the outlet is coordinated to meet the rapid and efficient hydrogen fueling.

The unloading module contains two sets of unloading channels to meet the hydrogen fueling demand during peak hours. The nitrogen purge system is installed in the container for purging the pipeline and supplying the instrument air.

The station control system takes the data acquisition control system and the host computer as the core to form an integrated monitoring system. It realizes the monitoring of the whole production process.